Product Description

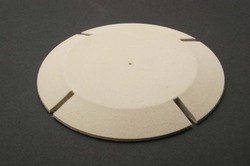

While climbing on the success ladder, it has become increasingly important for us to deliver a precisely tested and high grade assortment of Split And Bevel Laps. The offered laps are manufactured using best grade raw material and contemporary technology. We promise our clients that our range is quality examined on predefined parameters, in order to meet industry standards. Apart from this, our esteemed clients can avail the entire assortment, as per their needs, at highly competitive prices.

Precision Engineering for Superior PolishingEach Split Bevel Lap is meticulously precision-machined and bonded to deliver uniform results during the polishing and lapping of gemstones, metals, and optical components. Their smooth, embedded abrasive grits ensure consistent surface finishes, making them an ideal choice for industrial and professional applications.

Customizable Options AvailableWhether you need specific diameters, thicknesses, or custom grit sizes, these laps can be tailored to your unique polishing requirements. Their split bevel edge enhances adaptability to a range of surfaces, providing precise results with minimal effort.

Reliable and Durable PerformanceDesigned for repeated use, Split Bevel Laps feature high endurance against operational heat (up to 120C) and maintain their structure over time. The combination of high-grade cast iron or mild steel with a robust bonded abrasive coating ensures long working life and reliable performance with minimal maintenance.

FAQs of Split Bevel Laps:

Q: How are Split Bevel Laps used in the precision polishing process?

A: Split Bevel Laps are mounted onto standard lapidary or polishing machines. Their bevel edge and embedded abrasive grits efficiently polish gemstones, metals, or optical components by facilitating smooth and consistent contact, resulting in a superior, even surface finish.

Q: What customization options are available for Split Bevel Laps?

A: You can request custom sizes, thicknesses, and grit specifications to match your particular application. Whether you need a specific diameter (100 mm to 300 mm) or unique grit (120 to 3000 mesh), manufacturing adjustments are available to suit your workflow.

Q: When should a resin bonded versus a metal bonded Split Bevel Lap be selected?

A: A resin bonded lap is ideal when flexibility and fine finishing are needed, particularly for delicate gemstones. Metal bonded laps offer greater durability and are best for robust applications, such as heavy-duty metal or optical component polishing.

Q: Where can these laps be used effectively?

A: These laps are best used in lapidary studios, jewelry workshops, gemstone processing units, optical labs, and metal finishing facilities, making them suitable for industrial polishing and lapping tasks across multiple sectors.

Q: What benefits do split bevel edges provide during polishing?

A: The precision split bevel edge enhances lap adaptability by allowing the abrasive surface to conform gently to varied contours. This results in better pressure distribution, reducing polishing time while maintaining high precision and minimizing risk of edge damage.

Q: How can users maintain and clean Split Bevel Laps for repeated use?

A: After use, the laps can typically be cleaned with mild solvents or water depending on the bonding material. Their robust surface construction ensures that embedded abrasive grits remain effective through multiple cycles, provided the lap is properly maintained and free of debris.

Q: What makes these laps suitable for high-temperature polishing environments?

A: Constructed from high-grade cast iron or mild steel with strong bonding agents, these laps withstand operating temperatures up to 120C without deformation or loss of abrasive aggregate, ensuring consistent performance during demanding polishing tasks.