Product Description

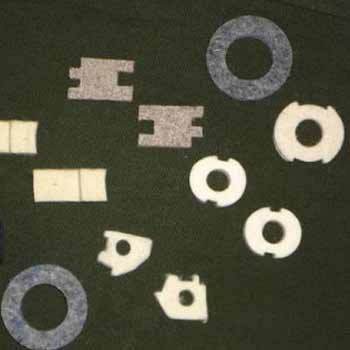

Felt Components is a textile material that is produced by matting, condensing and pressing fibers together. Felt can be made of natural fibers. The offered felt component is made by using best quality raw material and modern methodology by our workface. Felt Components due to its lightweight but durable nature are extensively being used in various forms and shapes in the manufacture of modern automobiles.

Customizable to Your SpecificationsWe provide felt components tailored exactly to your requirements in terms of shape, thickness, color, and dimensions. Whether you need die-cut gaskets, molded washers, or insulation pads, our expert team ensures each piece meets your exact industrial demands. Flexibility in design allows for a perfect fit and performance in every application.

Superior Performance for Industrial UseOur felt components are engineered for durability, flexibility, and precision. They offer excellent tensile strength, moderate oil resistance, and low water absorption, making them ideal for applications such as damping, sealing, polishing, and insulating. The smooth, dense texture enhances functionality in harsh environments.

Efficient Delivery and Bulk HandlingWe cater to distributor, exporter, manufacturer, and trader needs with order-specific minimum quantities and reliable packing options. Secure box or carton packaging and a lead time of 7-10 days ensure your supplies arrive protected and on schedule, streamlining your procurement process.

FAQs of Felt Component:

Q: How can I order a felt component with custom dimensions and shapes?

A: You can provide your drawings or detailed specifications for the required shape, thickness, and size when placing an order. We manufacture felt components as per your requirements using precision cutting, die-cutting, or molding techniques.

Q: What are the typical industrial uses for these felt components?

A: Our components are commonly employed as gaskets, washers, insulation pads, damping elements, and polishing wheels. Their flexibility and resilience make them suitable for preventing vibration, sound absorption, sealing, and surface finishing in various machines and equipment.

Q: When should I choose felt with optional adhesive backing?

A: Select felt with adhesive backing when easy installation is required or when bonding to another surface is necessary. This feature is beneficial for applications such as insulation or damping where secure placement is important.

Q: Where do you deliver your felt products?

A: We supply and export our felt components throughout India and internationally. Our robust packaging ensures the product reaches you in optimal condition, wherever your business operates.

Q: What is the process for manufacturing these felt components?

A: Our components are produced using needle punching and pressing techniques, utilizing high-quality wool felt. After forming the base material, components are cut, die-cut, or molded into specific shapes and inspected for quality and precision.

Q: What are the main benefits of using your custom felt components?

A: Our felt parts offer precision fit, durability, low water absorption, moderate oil resistance, and efficient sound absorption. They are engineered for long-lasting performance and can withstand temperatures up to 80C.