Product Description

We are occupied in providing superior quality of Enamelling Felts to our respected clients. These are manufacture with high quality of raw material. These products is available in various design & sizes as per requirement of customers. Customers can avail these products at very competitive and affordable prices.

Specialized Wool Felt for Enamelling ApplicationsOur Enamelling Felts deliver trusted performance in wire, glass, and enamelling operations. Made using advanced needle punching and pressing techniques, they provide a non-abrasive, high-durability surface ideal for sensitive tasks. The felts high tensile strength and temperature resistance up to 180C make them an industry favorite.

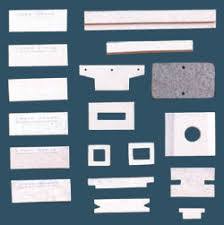

Flexible and Customizable SolutionsWhether you require straight-cut or die-cut edges, our felts can be tailored precisely to your needs. Available in a selection of thicknesses and widths, they fit a variety of industrial setups, from intricate jewellery work to large-scale electrical assemblies. Cutting tolerance ensures accuracy and reliability in every order.

Eco-Friendly and Safe for Sensitive EnvironmentsOur odourless, uncoated felts are manufactured with sustainability in mind. Thanks to their eco-friendly wool material and low moisture absorption, theyre safe and efficient across demanding environments. Their smooth texture and non-abrasive properties help protect delicate surfaces during use.

FAQs of Enamelling Felts:

Q: How are Enamelling Felts typically used in industrial applications?

A: Enamelling Felts are widely used for cleaning, polishing, and insulating tasks in the glass, wire, jewellery, and transformer sectors. Their non-abrasive surface is gentle on delicate items, while the felts flexibility and temperature resistance allow for reliable usage in high-temperature environments.

Q: What customization options are available for Enamelling Felts?

A: These felts can be customized in terms of length, width (10 cm to 150 cm), thickness (4-20 mm), color, and shape. Edge treatments can be straight-cut or die-cut, and cutting tolerances are maintained within 0.5 mm for precision. Custom shapes are available to suit specific operational needs.

Q: When should I consider using Enamelling Felt sheets versus rolls?

A: Sheets are ideal for flat surface coverage or tasks where defined dimensions are needed, such as in transformer or electrical insulations. Rolls offer flexibility for continuous processes or where varying lengths are required. Both forms can be cut to custom sizes as per customer requirements.

Q: Where are Enamelling Felts most commonly used?

A: These felts are extensively utilized in the glass industry, jewellery making, wire enamelling, transformer insulation, and various electrical applications. Their solid construction and high durability make them suitable for handling and protecting sensitive components.

Q: What makes wool felt a preferred material for enamelling felts?

A: Wool felt offers a smooth and soft texture, high tensile strength, natural flexibility, and excellent temperature resistance. It is also eco-friendly, odorless, and has low moisture absorption, ensuring it doesnt compromise the integrity of materials during sensitive industrial processes.

Q: How does the enamelling felt manufacturing process ensure quality and performance?

A: Our felts are produced using both needle punched and pressed techniques, resulting in a dense and uniform structure. This process guarantees high durability, even density (0.30 g/cm), and a smooth finish, which are critical for consistent industrial performance.

Q: What are the main benefits of using your Enamelling Felts?

A: Key benefits include high durability, non-abrasive and flexible usage, resistance to moisture and temperatures up to 180C, and the ability to customize for specific tasks. Their eco-friendly composition and odorless nature make them suitable for sensitive environments.